Tohoku earthquake critically affects world's mineral supplies

In addition to its other effects, the magnitude 9.0 Tohoku earthquake that struck northeast Japan on March 11, 2011, will affect Japan’s and the world’s supply of some minerals, at least temporarily. Up to one-quarter of the world’s iodine and one-third of Japan’s cement production may be affected. The USGS report indicates that the area affected by the earthquake is home to eight iodine plants and nine cement plants, as well as 15 other nonfuel mineral processing facilities and four limestone mines.

Factors that affect these mines and mineral processing plants include not only the physical damage inflicted on them by the earthquake, but also the damage done to the surrounding infrastructure. Mineral extraction and processing facilities require large quantities of electricity, and much of Japan’s electrical power capability in the affected area was severely damaged. Some mineral facilities that sustained no damage from the earthquake have been forced to shut down because of limits placed on electricity usage. Transportation infrastructure is also important to mineral processing and extraction, as highways, railroads, and ports are required both to supply raw materials and to ship finished products. Japanese media outlets have reported damage to 12 ports in area, as well as widespread railroad damage.

Japan is the world’s second leading iodine producer, after Chile, with roughly 33 percent of the world’s total. The eight affected refineries alone have the capacity to produce 25 percent of the world’s iodine.

Iodine is used primarily in liquid-crystal displays for electronic devices and x-ray contrast media. High doses of nonradioactive iodine (usually as potassium iodide) can protect people exposed to high levels of radiation from health problems later in life.

In addition to iodine, Japan is a leading source of titanium metal, and its facilities in the affected area have the ability to produce 10 percent of the world’s titanium metal. (USGS)

It feels a little callous writing about Japan with respect to precious metals after the country suffered such a terrible tragedy. However, I think it's worth discussing because there's a lesson in it for all of us. In fact, I think the moral could be couched in terms of a warning.

It's commonly known in Japanese culture that citizens harbor gold to protect against unforeseen events. The gold isn't sold unless it's needed for an emergency. With respect to the Japanese government, the country's central bank is the 8th largest holder of the metal (including the IMF and GLD). Beyond investment, Japan represents about 6% of worldwide gold fabrication (excluding investment demand), the majority of which is in electronics. Scrap recycling has been heavy in recent years, while jewelry demand is low….

Premiums for gold and silver there have risen in response to the disasters, which isn't surprising. Japanese investors scrambled for physical metals after the earthquake, immediately pushing premiums to three-year highs. And it wasn't just buyers in the earthquake, tsunami and nuclear-plant zones; those in less affected parts of the nation have been rushing to buy precious metals, too. The end result is that available supply has been glutted. (MineWeb)

Mining in Japan was a rapidly declining industry in the 1980s. Domestic coal production shrank from a peak of 55 million tons in 1960 to slightly more than 16 million tons in 1985, while coal imports grew to nearly 91 million tons in 1987. Domestic coal mining companies faced cheap coal imports and high production costs, which caused them chronic deficits in the 1980s. In the late 1980s, Japan's approximately 1 million tons of coal reserves were mostly hard coal used for coking. Most of the coal Japan consumed is used to produce electric power.

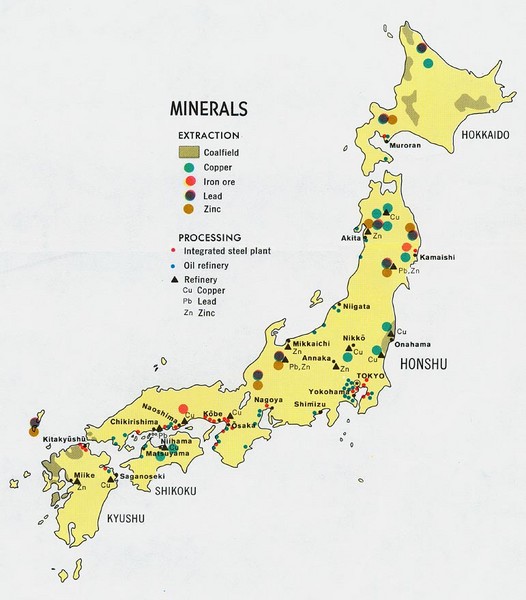

Japanese coal is found at the extreme ends of the country, in Hokkaidō and Kyūshū, which have, respectively, 45 and 40 percent of the country's coal deposits. Kyūshū's coal is generally of poor quality and hard to extract, but the proximity of the Kyūshū mines to ports facilitates transportation. In Hokkaido, the coal seams are wider and can be worked mechanically, and the quality of the coal is good. Unfortunately, these mines are located well inland, making transportation difficult. In most Japanese coal mines, inclined galleries, which extended in some places to 9.71 kilometers underground, were used instead of pits. This arrangement is costly, despite the installation of moving platforms. The result is that a miner's daily output is far less than in Western Europe and the United States and domestic coal costs far more than imported coal. (Wikipedia)

- Mines and Mineral Processing Facilities in the Vicinity of the March 11, 2011, Earthquake in Northern Honshu, Japan

- Coal truths in the Japan aftermath (BusinessLine)

- Mining in Japan – Overview

- Ministry of Economy, Transportation and Industry of Japan

- Geological Survey of Japan

- World mineral map

Commenting rules and guidelines

We value the thoughts and opinions of our readers and welcome healthy discussions on our website. In order to maintain a respectful and positive community, we ask that all commenters follow these rules:

We reserve the right to remove any comments that violate these rules. By commenting on our website, you agree to abide by these guidelines. Thank you for helping to create a positive and welcoming environment for all.