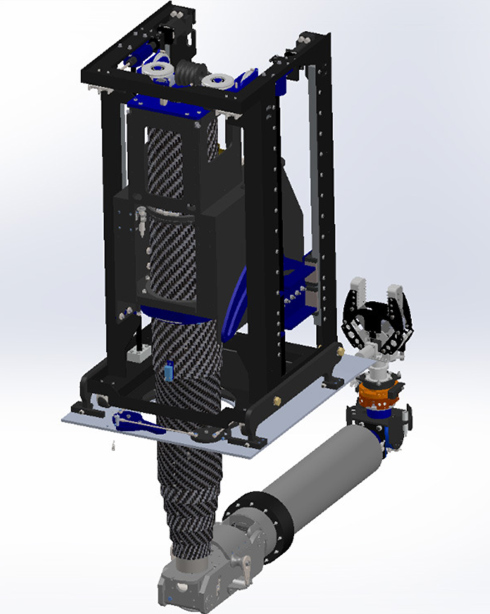

Advanced robotic arm to repair primary containment leaks at the damaged Fukushima Daiichi NPP

Kurion Inc., nuclear and hazardous waste management corporation, announced in its press release it was awarded a contract to develop an advanced robotic arm to repair primary containment leaks within the Unit 2 Reactor of the Fukushima Daiichi Nuclear Power Plant in Japan. The Fukushima Repair Manipulator (FRM), is expected to be ready for a targeted deployment mid-2016.

The system will grant plant workers unprecedented access to the reactor's open holes and obstacles, enabling them to plug cracks in the vent tubes and torus all from the safety of their remote control stations. Kurion’s sophisticated system will include a robotic arm outfitted with advanced cutting, water-jet and grouting tools and will feature new automatic control sequences to guide these complex tasks.

John Raymont, Kurion's founder and president said the company has applied their innovative technologies throughout the plant during the last three years to purify hazardous water and identify repair needs.

"Now, the adoption of Kurion’s Fukushima Repair Manipulator marks another critical step in accelerating the ongoing cleanup of the plant," he said.

Graphic rendering of the Fukushima Repair Manipulator (FRM). Image credit: Kurion Inc.

“Access to radioactive and hazardous environments is a crucial piece of the waste management puzzle,” said Kurion's CEO Bill Gallo.

“Each project is unique, posing an engineering challenge that demands a custom robotics systems that can complete tasks where humans cannot operate. In addition to robotic-centric projects, such as the remote systems developed for the Fukushima Daiichi Nuclear Power Plant, robotics systems also play a critical support role for Kurion’s vitrification technologies, where remote operations are required.”

Kurion assisted in the first phase with the development and delivery of the Fukushima Inspection Manipulator (FIM), a robotic system tasked with searching for the causes of the leaks. The first inspection was completed ahead of schedule and produced the necessary information to move forward with the second phase of the repair efforts. The FIM is currently inspecting seven additional locations in the reactor building and is scheduled to complete this task in March 2015.

Once the leaks are patched by the Fukushima Repair Manipulator, plant workers are expected to finally have the opportunity to remove the damaged fuel and debris from the reactor, drastically decreasing the output of contaminated water that is currently used to cool the core.

Source: Kurion Inc.

Featured image credit: Greg Webb / IAEA

Commenting rules and guidelines

We value the thoughts and opinions of our readers and welcome healthy discussions on our website. In order to maintain a respectful and positive community, we ask that all commenters follow these rules:

We reserve the right to remove any comments that violate these rules. By commenting on our website, you agree to abide by these guidelines. Thank you for helping to create a positive and welcoming environment for all.